SHANDONG WUGANG METAL MANUFACTURER CO., LTD

All categories

Contact

Room 1211, Zhongze Building, Huaiyin District, Jinan city zip code: 250000

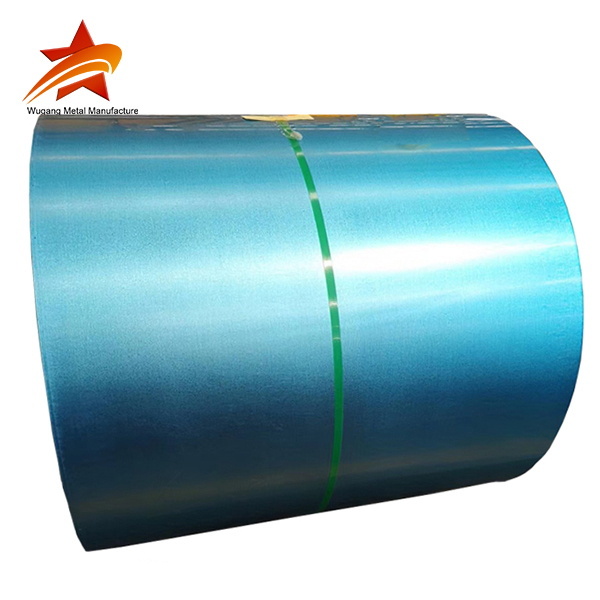

Galvalume Steel Coil

The coating composition of Galvalume Steel Coil is composed of 55% aluminum, 43.4% zinc and 1.6% silicon by weight. Mainly used in the construction industry, automotive industry, air conditioners, automobiles, muffler, hose clamps, heat shields, buckets, garden tools, home appliance industry, heat exchanger and other products.

Category:

Galvalume Steel Coil/Strip

Keywords:

Galvalume Steel Coil

Galvalume Steel Coil is also called Aluminum-Zinc Alloy Coated Steel coil, Zinc-alume steel coil, aluminized zinc steel coil (alu-zinc steel coil), SGLC, The galvalume metal is composed of 55% aluminium, 43.4% zinc and 1.6% silicon solidified at 600 ℃. Its whole structure consists of aluminium-iron-silicon-zinc, forming a compact quaternary crystal alloy. The surface of the galvalume steel coil/ sheet is characterized by smooth, flat and gorgeous stars, and its base color is silver white.

The special coating structure makes it have excellent corrosion resistance. The normal service life of galvalume steel sheet is up to 25a, and its heat resistance is good. It can be used in high temperature environment at 315 ℃. The adhesion between coating and paint film is good, and it has good processing performance. It can be punched, sheared and welded. The surface conductivity is very good.

Weight Of Al-Zn Coating

Mechanical Properties

Advantages of Galvalume Steel Coil/Sheet:

1.Corrosion resistance:When alu-zinc is abraded, aluminum forms a dense layer of alumina that prevents further corrosion of the corrosive material inside.

2.Heat resistance:Aluminum zinc alloy steel has good heat resistance and can withstand high temperatures of more than 300 degrees Celsius.

3.Thermal reflexes:The heat reflectivity of Al-Zn steel plate is very high, which is two times that of galvanized steel sheet.

4.Economical efficiency: Since the density of 55% AL-Zn is smaller than the density of Zn, the aluminum-zinc-plated steel sheet is more than 3% larger than the area of the plated steel sheet when the weight is the same and the thickness of the gold-plated layer is the same.

5.Easy painted:The galvanized sheet has perfect adhesion to the paint, eliminating the need for pre-treatment and weathering of the paint job.The coating material on the galvanized steel sheet has excellent adhesion and can be directly coated on advertising boards and common boards without pre-treatment such as weathering.

GL COIL Coating Layer

Galvalume Steel Roll Coil detail

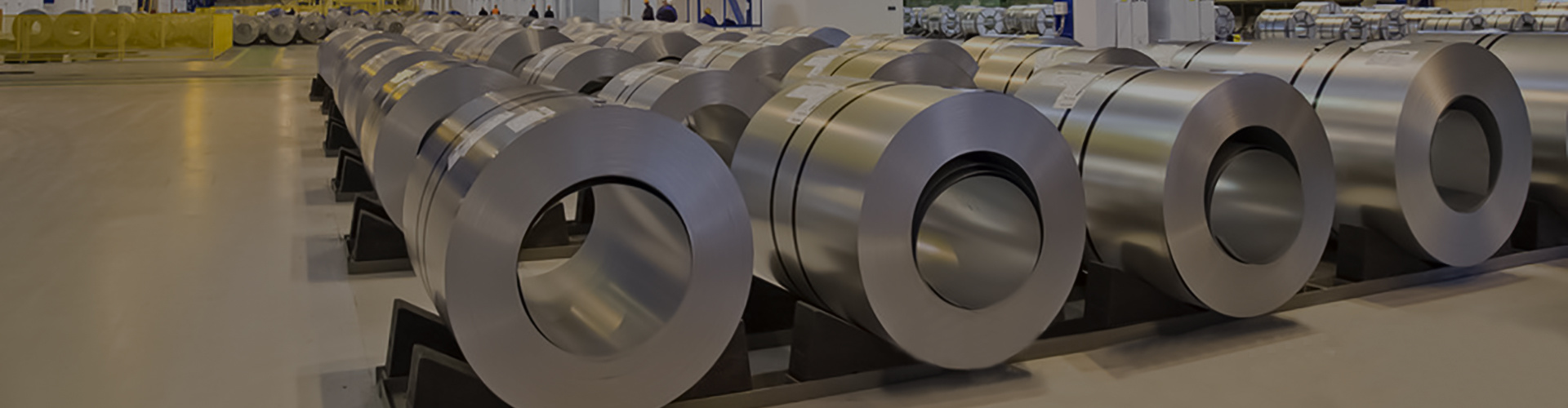

Galvalume Steel Coil In Stock

Detailed steps of processing Galvalume Steel Coil:

step 1:

Pre-treatment: After the cold-rolled steel coil arrives at the galvanizing workshop, it goes through the uncoiler, degreasing section and reduction furnace to clean the steel coil and reduce its composition to a level that can be galvanized.

Step 2:

Middle section: The most critical technology is this step. After passing through the zinc pot, the surface of the steel plate is coated with a zinc layer. After coming out of the zinc pot, it is cooled by a cooling tower and shaped.

Step 3:

Post-processing: The steel plate finally enters the post-processing stage after various processes. After finishing, straightening and passivation, and finally coiling.

Galvalume Steel Coil usages

Applications of Galvalume Steel Coil/Sheet:

Appliance industry

Washing machines, refrigerators, TV sets, air conditioning and ventilation systems, outer panels, explosion-proof strips, solar water heaters and electrical parts.

Industrial instrument

Electric control cabinets, industrial refrigeration equipment, vending machines.

Architecture

Roofs and facades, garage doors, fencing and shutters of civil and industrial buildings.

Agriculture

Pig farms, chicken houses, granaries, greenhouse pipes, etc.

Other

Mufflers, heat shields for exhaust pipes and catalytic converters, auto parts under the frame, signboards for highways.

Q:What kind of work does your company do?

A:Our company is a professional manufacturer.

We mainly produces aluminum/stainless/galvanized/galvalume/ppgi/ppgl/ppal products.

Q:What is your terms of payment?

A:We accept T/T, L/C, etc.

The payment method can be negotiated by both parties according to the actual situation.

Q:What are the advantages of your company?

A:(1): Prime quality and reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be customized as your requirements.

Q:How long is your delivery time?

A:Generally it is 3-7 days if the goods are in stock or it is 7-15 days if the goods are not in stock, it is according to quantity.

Q:Do you provide free samples?

A:Yes, we can provide free sample for testing, buyer should bear all the shipping costs.

previous page

next page

previous page

next page

Online consultation

Related Products

Hot Dipped Galvanized Steel Coil

Wugang Metal® supplies hot-dip galvanized coil and electro-galvanized coil, and supports customized spangle. Regular spangle, small spangle, large spangle and zero spangle have a large number of factory stocks, and can be shipped within 3-5 days. The grade of galvanized base material can choose DX51D+Z, DX52D+Z, DX53D+Z, DX54D+Z, and the thickness of zinc coating can choose z20-z275.

Alu-Zinc Galvalume Steel Strip

Galvalume Steel Strip has many excellent characteristics: strong corrosion resistance, 3 times that of pure galvanized sheet; beautiful surface sequins, anti-fingerprint, can be used as building outer plate. The corrosion resistance of Galvalume Steel Strip is mainly due to aluminum, the protective effect of aluminum. When the zinc is worn away, the aluminum forms a dense layer of aluminum oxide that prevents corrosion-resistant substances from corroding the interior further.

Antifinger Print Galvalume Steel Coil Strip

Antifinger Print Galvalume Steel Coil Strip is also known as Antifinger Print Al-Zn alloy Steel Coil Strip, zinc alloy steel, aluzinc steel, SGLC, galvalume metal is composed of 55% aluminum, 43.4% zinc and 1.6% silicon, Solidified at 600°C. Its overall structure is composed of aluminum-iron-silicon-zinc, forming a dense quaternary crystal alloy. The surface of Antifinger Print Galvalume Steel Coil Strip is characterized by smooth, flat and brilliant stars, and its base color is silvery white. The special coating structure makes it have excellent corrosion resistance. The normal service life of galvanized steel plate can reach 25a, and the heat resistance is good.

G550 Galvalume Steel Coil Strip

The coating composition consisted of 55% aluminum, 43.4% zinc and 1.6% silicon by weight. The production process of galvanized steel sheet is similar to that of G550 Galvalume Steel Coil Strip and aluminized sheet, both of which are a continuous melt coating process. The corrosion resistance of 55% Al-Zn alloy coated G550 Galvalume Steel Coil Strip is better than that of galvanized steel sheet of the same thickness when exposed to the same environment on both sides. The G550 Galvalume Steel Coil Strip with 55% Al-Zn alloy coating not only has good corrosion resistance, but also the color-coated products have excellent adhesion and flexibility.